As suppliers of parts and materials, across all industries, endure the ongoing global struggle, Masterwood GB was facing delivery times of up to six months for new machines. As the demand for these is still going strong, Masterwood GB have pre-ordered a range of machines, to go into production at the Rimini factory in Italy.

The machines are built to mid-range specifications, with the ability to retrofit additional options, such as waste conveyors and a fourth axis, so every machine can meet the customer’s requirements without the need to compromise. Alternatively, items initially added to the machine can be removed if not required, to avoid unnecessary costs for the customer.

When a Masterwood customer in Northern Ireland found their 18-year-old CNC was no longer viable for repair, the decision was made to purchase a new Masterwood Project 470L. As the machine was near completion when the order was placed in early October, delivery from Italy and installation was completed in just 4 weeks.

The current range of stock machines available from Masterwood GB includes the versatile 4-axis Project 470L, also available as 3-axis.

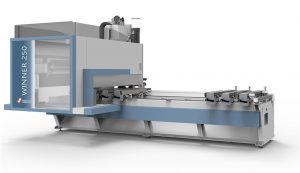

Winner 250 – Masterwood’s entry level short bed CNC; suitable for doors, windows, cabinets and other bespoke work.

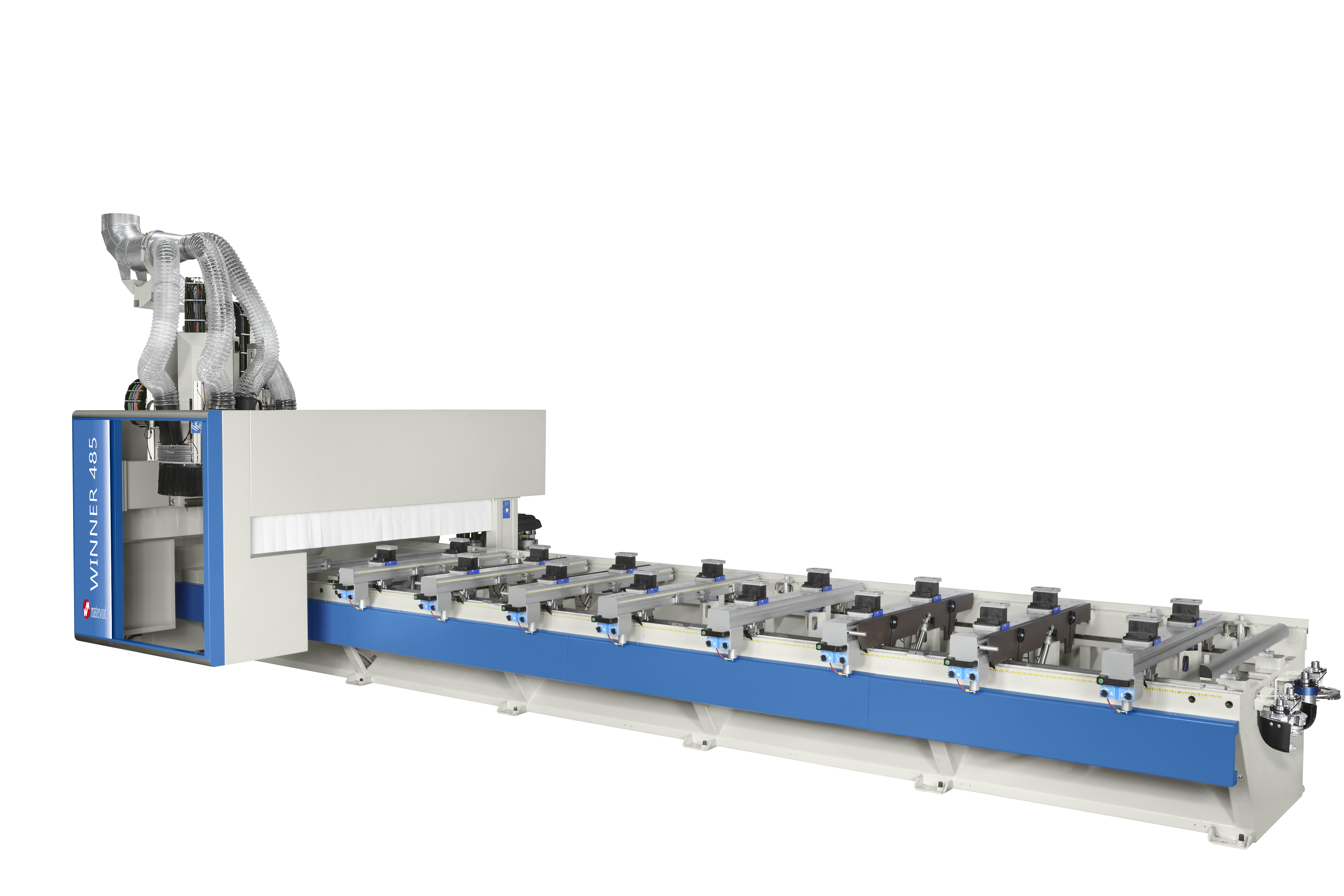

Winner 485L – Fixed specification full 5-axis long bed CNC.

TF 600 KT – The latest addition to the Masterwood CNC drilling range. High speed drilling on all six faces of a panel, plus routering above and below with a six-position tool changer.