As suppliers of parts and materials, across all industries, endure the ongoing global struggle, Masterwood GB was facing delivery times of up to six months for new machines. As the demand for these is still going strong, Masterwood GB have pre-ordered a range of machines, to go into production at the Rimini factory in Italy.

The machines are built to mid-range specifications, with the ability to retrofit additional options, such as waste conveyors and a fourth axis, so every machine can meet the customer’s requirements without the need to compromise. Alternatively, items initially added to the machine can be removed if not required, to avoid unnecessary costs for the customer.

When a Masterwood customer in Northern Ireland found their 18-year-old CNC was no longer viable for repair, the decision was made to purchase a new Masterwood Project 470L. As the machine was near completion when the order was placed in early October, delivery from Italy and installation was completed in just 4 weeks.

The current range of stock machines available from Masterwood GB includes the versatile 4-axis Project 470L, also available as 3-axis.

Winner 250 – Masterwood’s entry level short bed CNC; suitable for doors, windows, cabinets and other bespoke work.

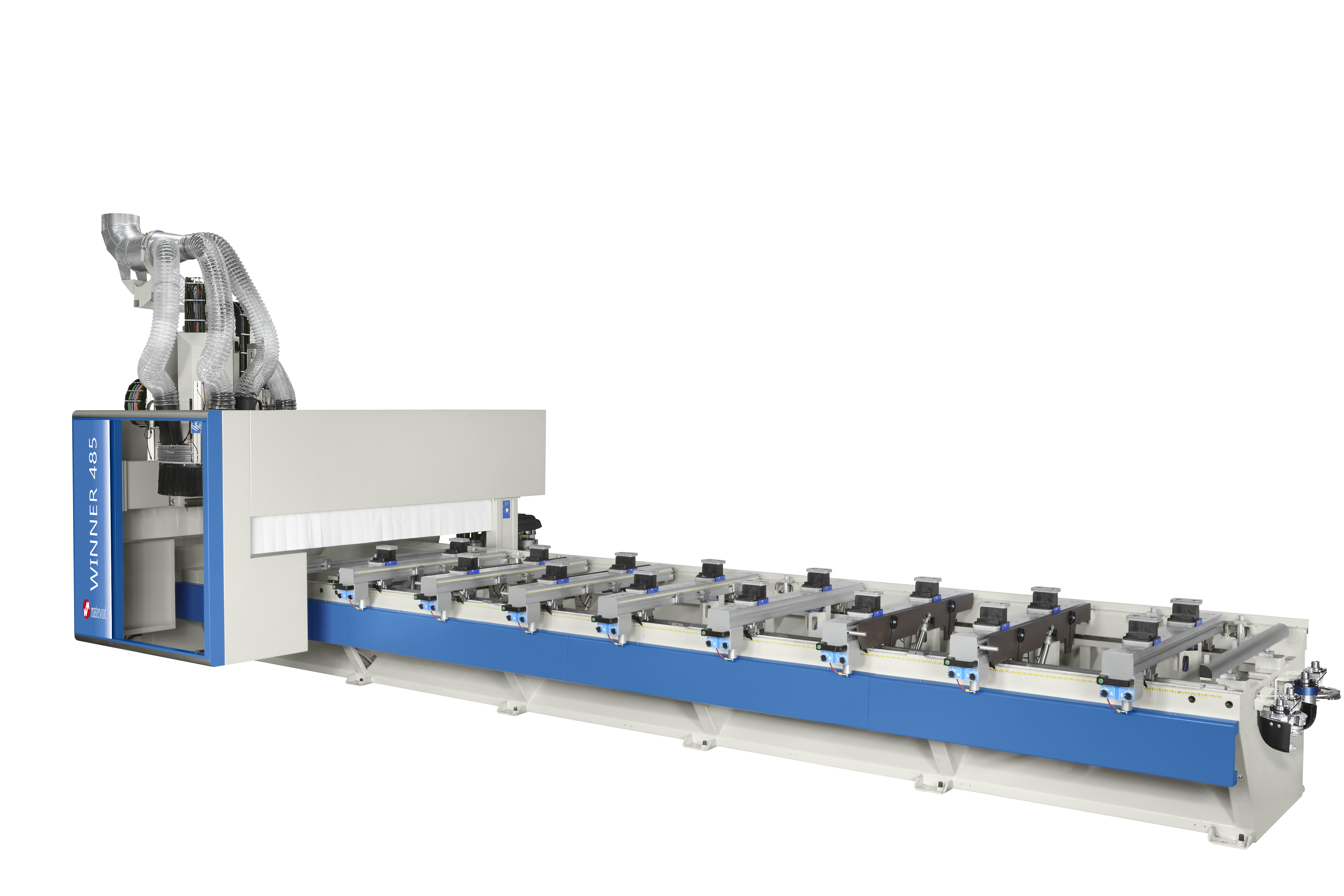

Winner 485L – Fixed specification full 5-axis long bed CNC.

TF 600 KT – The latest addition to the Masterwood CNC drilling range. High speed drilling on all six faces of a panel, plus routering above and below with a six-position tool changer.

Masterwood GB celebrated their first Open House dates since moving to their new showroom with a great turnout of new and existing customers across the 4-day event. Customers had the chance to view a full range of Masterwood machines including the new high-speed drilling FT600s and MS320 Beam saw which are manufactured by parent company, KDT Machinery.

Through-out the 4 days, various demonstrations were run on the showroom machines to show off each machine’s capabilities.

On the Pod and rail 5-axis CNC, one that grabbed a lot of attention was a full window frame and sash using Whitehill profile blocks. Masterwood GB sales director, Dave Kennard, said “Although 5-axis isn’t required for window production, we were able to show customers a speed and efficiency that can be achieved with a CNC machine to produce a complete window”. A traditional box window, designed using the MasterWindow and MasterWorks software packages, was also run on the pod and rail CNC, fully machining a sill, head, and a pair of pulley jams in approximately 15 minutes, a fraction of the time that a skilled woodworker would require to do the same work.

The new TF-600S drilling machine did not disappoint. Customers were impressed with its high-speed work rate and ability to work on all 6 faces of a panel, producing a cabinet panel containing 30 holes, in just 10 seconds. The machine uses twin grippers to securely clamp the panel, and an air blower table to allow quick and smooth movement in and out of the working area. These machines are standard with drill heads and routers above and below and higher levels can have the option of tool changing.

MS-320 Beam Saw – The long-awaited beam saw from Masterwood, in partnership with KDT, generated a lot of interest with the speed that panels could be cut from full size sheets and the quality of cut. The basic software allows panels sizes to be set and then to be optimized into sheet sizes to get the most efficient layouts with minimum waste.

On the flat bed MW1225KS, a popular demo from the W18 exhibition, a dinosaur 3D jigsaw. The programs are created using Master3D software, and the design is nested together to get the maximum number of components out of sheet material. The current showroom model is a 4-axis version and allows the aggregate heads required for Lamello P-System joints to be used.

Speedy II – The compact drilling machine demonstrated a simple cabinet being fully machined and using the Lamello jointing system. The machine is currently available as an ex-demo model. Contact MWGB office for more information. The Speedy is proving to be a very popular model with its main drilling facilities plus the added six position tool changer, it makes the machine very versatile for “One Offs” or for use with larger quantities of panels where in and out feed tables help.

Our staff at Masterwood GB would like to thank all companies and customers who attended the open house to see the machinery and software packages we have to offer, as well as Whitehill and Lamello for their presence at the open house.

The Masterwood GB showroom is available for machine and software demos on a full range of products, at your convenience. To book a visit and see how Masterwood can change your business, email – office@masterwoodgb.co.uk or call 01293 402700

Masterwood GB will be hosting their first ‘Open House’ at their Gatwick showroom, from 18th to 21st May 2022.

There will be demonstrations on:

• Solid Core & Timber Frame doorsets • Windows/Traditional Box Windows • Cabinets & Face Framing • Stairs • Nesting Panels & Shapes • Full 5-Axis / 3D

These machines will be on show:

• Project 385L – 5 Axis pod & rail • MW 15.38 – Nesting Flatbed • Speedy II – Drilling + Routering • MW320s – Beam Saw • TF600s – High-Speed Drilling + Routering

TF600S – In addition to the original Project TF100/Speedy, Masterwood now offers a wider range of drilling machines for the panel market. The Master Drill series, which is available in three versions, has the advantage of working above and below simultaneously, thanks to the Smart table, for continuous workpiece support and patented air bed tables.The machines can have vertical & horizontal drilling heads above and below the bed, plus the option for vertical routers; these combinations and the twin gripper feed system ensure fast and accurate machining.Programmes are easy to generate in the Masterwood CAD/CAM software, and can be used with bar codes and scanners for fast automated production.Options of infeed and outfeed tables, to help speed up production time, are available amongst the three models.

Beam Saw – Having already been sold around Europe since its release, the first Beam Saw by Masterwood will be arriving in the UK in 2022.The machines are available in three levels to suit all requirements of production and workshop; these are heavy-build machines, using leading manufacturer’s parts, to ensure high and long-lasting accuracy.